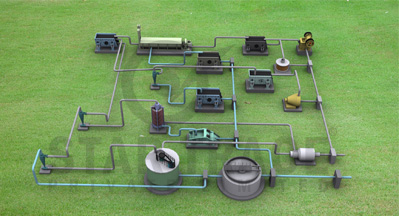

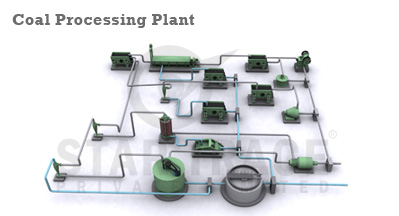

Coal Processing Plants

Star Trace offers turnkey solutions for coal processing plants. We are one of the leading project suppliers for zircon plants and we work closely with our customers to fulfill their specific needs for a customized packaged solution. Specialized in the fabrication of these machines for 25 years and this enables us to be in a leading position in the field of Coal Processing plant & equipment.

Slurry Pumps

STAR TRACE is one of the most well recognized manufacturers of heavy duty, medium duty slurry and process pumps, vertical slurry pumps, ash slurry pumps, process pumps in India today.

Our company manufacturers advanced slurry pumps and process pumps. Our pump handle tougher abrasive solids and slurry found in mining, steel and glass industries.

Suspended Permanent Magnet

STAR TRACE suspended permanent magnets (SPM) are designed for high separation performance in over the belt conveyor applications.

These heavy duty permanent magnets incorporating all welded construction are particularly effective in removing tramp metal in high volume applications.

The series is designed for heavier applications, i.e., coal, grain etc.

Options- Stainless Steel plates

- Turn buckles.

- Easy clean stripper pan.

- Suspension kit for fixed mounting to conveyor frame.

- Permanent magnetic field.

- No electrical hook ups.

- Compact design.

- Heavy duty impact plate.

- Stainless Steel angled cleats.

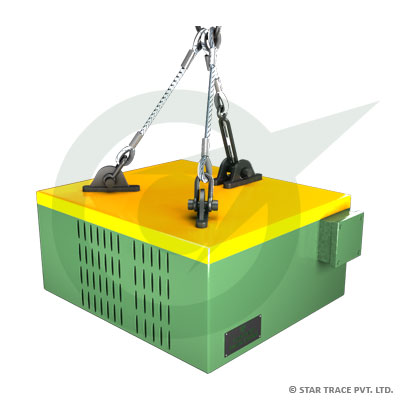

Suspended Electro Magnet

Suspended Electromagnets are designed for separation of ferrous metal from a variety of overthe belt conveyor applications.

Proven in industries such as mining, recycling, tire shredding, pulp & paper, construction & demolition. Star Trace Suspended Electromagnets offer superior strength and reliability.

Used in high volume low (less than 150mm) product depth applications, suspended electromagnets offer the ability to be turned on & off.

Installation options include in-line and cross-belt configurations to meet the specific needs of your applications.

As the product on a conveyor belt flows under the powerful magnetic field, ferrous material is pulled out of the product flow and held to the face of the magnet. When using a manual clean model, the collected tramp metal is held in place for as long as the unit has power. In order to clean the unit, the power source must simply be turned off, which instantly releases the metal from the magnets hold.

Features- Non-combustible coolant.

- External expansion tank.

- Insulated copper coils / aluminium coils.

- Manganese impact plate.

- Lift lugs.

- 1 year limited warranty on coils.

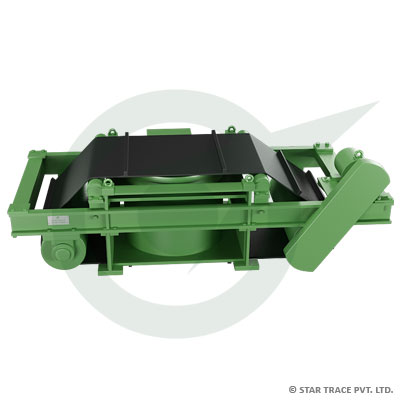

Overband Permanent Magnetic Separator

STAR TRACE Permanent Magnetic Over band separators are powered by ceramic focused flux, strontium ferrite magnets for superior coercive force.

The magnetism in these equipment is produced by an internal assembly of the above magnetic material. This assembly is enclosed in a non-magnetic housing.

Star Trace design concentrates attractive power on the surface where it is needed most.

The magnetic strength of the permanent magnet will match that of the corresponding size of the electromagnet used for the same application.

In Over band permanent magnetic separator, continuous cleaning is made possible by a heavy duty clad belt that encircles the magnet on a series of rotating pulleys.

As ferrous metal is attracted and held by the magnet, the moving belt carries the collected metal outside of the magnetic field where it is then released beyond the product flow.

Special Features- For extra protection from tramp iron.

- For increased product cleaning .

- For heavy duty separation.

Overband Electro Magnetic Separator

STAR TRACE Overband electro magnetic consist of an air cooled or oil cooled suspension magnet, supporting structure for the discharge belt with drive drum, tail drum and 2 additional idlers where necessary.

The drums, idlers are mounted on suitable self aligning bearings. A suitable geared-motor or motor coupled to gear box is used to drive the discharge belt.

The discharge belt is a rubber/canvas or rubber/nylon belt with several plies and cleats.

For re-tightening the discharge belt, the fixed axle of the tail drum is fitted with a tensioning device.

STAR TRACE offers a wide range of standard Electro overband magnetic separators suitable for belt width upto 2500mm and operating heights upto 1100mm.

Bucket Elevators

Bucket Elevators are among the most common conveyors used for making vertical lifts of bulk materials. The materials being conveyed can vary over a wide range of sizes from powders to pellets. Most of these bulk materials inherently produce dusty conditions within the bucket elevators, creating explosive hazards.

In the grain storage and handling industry, the bucket elevator is considered to be the most dangerous piece of equipment in the process. Good housekeeping and explosion prevention strategies have reduced the average number of explosion per year but to do nothing to mitigate the destructive effects of explosions that do occur.

User IndustriesAgricultural, Chemical, Food, Pharmaceutical, Power, Wood Processing.

Rotary Shaft Kilns

STAR TRACE manufactures kilns cement plants. We have manufactured high-quality kilns, made of varied materials.

All kilns are excellent heat exchangers where heat is transferred in a variety of ways. We produce kilns which are made with precision and detailed accuracy.

They are highly durable and made with attention to each and every detail as provided by the client.

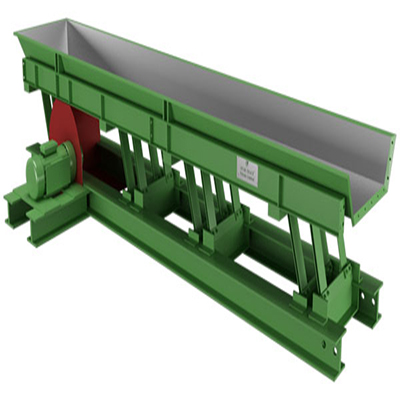

Vibrating Conveyors

Moves high volumes of material with low horsepower requirements. *Levels and orients material as it is conveyed, reducing surges to downstream equipment.

They are built in 10 foot long sections which are bolted together to make up a conveyor of the required length.

Odd length sections are available for use at the ends of the conveyor when the length is not a multiple of 10 feet.

Counter balanced design provides an extremely smooth running conveyor with reduced foundation and support structure requirements.

Mineral Jig

Theory Of OperationThe In-line pressure Jig is unique in its design and use of jigging concepts. The unit is fully encapsulated and pressurised and combines a circular bed with a moveable sieve action. The encapsulation allows the STPL to be completely filled with slurry and water.

As a result, slurry velocity is slowed and water surface tension eliminated improving recovery potential. The screen is pulsed vertically by a hydraulically driven shaft. Length of stroke and speed of up and down stroke can be varied to suit the application. Screen aperture and ragging dimension and material can also be altered for the application.

STAR TRACE pressure Jig is a high yield, high recovery gravity separation device. It has been successfully installed in both alluvial and hard rock applications.

Significant advantages have been achieved in grinding circuits where coarse heavy minerals or waste material have been recovered for preferential treatment prior to over grinding.

The mineral jig operated to recover free gold, sulphides, native copper, native silver, tin/tantalum, diamonds and garnet.

Installations are also planned for coal, lead remediation, magnetite, mineral sands and iron ore recovery. Typically units are installed in the recirculating load with STPL feed consisting of up to 14mm mill discharge or cyclone underflow.

Dewatering Feeder

We offer a high quality Dewatering Feeder which is used in various applications.

Features of our Dewatering Feeder are:- 900 x 1400mm dewatering feeder driven by two overhead mounted vibratory motors and single polyurethane drainage panels.

- Head feed to mineral processing equipments often contains excessive moisture adversely affecting the performance of such equipment.

- Star Trace dewatering feeders are designed to fulfill two basic requirements, remove the excess moisture and regulate the feed rate of the processing equipment.

- Polyurethane or stainless steel wedge wire screen panels on the feeder pan allow the water to pass through, drying the solids in the feed.

- The vibratory motors can either be mounted below and to the rear of the pan or overhead. Overhead mounting allows maximum area of drainage panel.

- The standard range of screen from 300mm x 900mm to 3000mm x 9000mm in single deck configuration.

Wet High Intensity Magnetic Separator

STAR TRACE pulsation high gradient magnetic separator include: STED-500, STED-1000, STED -1250, STED-500, STED-750, STED-2000, STED-2500 and STED-3000 etc and has been widely used in wet separation for weak magnetic metal ore such as hematite, limonite, siderite, chromites, limonite, wolfarm etc as well as iron separation for purification of non-metallic mineral, such as quartz, feldspar, nightline, fluorite, kaolin etc. Its separation ring is designed to be vertical fine ore is discharged by reverse flow and also with separation pulse device which settles the problem of being essay jammed in horizontal ring and traditional vertical ring from the very beginning. The magnetic material adopts our own patent products which can get higher magnetic intensity so as to get more powerful magnetic force improve the effect of separations. This series products with advanced to ore granularity, ore density and ore grade which realize the goal concentrations and good reclaimation.

Magnetic yoke fixed on the machine frame, which generate the strong magnetic field together with exciting coil. Rotary ring in the clockwise drived by the rotary device and goes through the magnetic field slowly. There are many separation boxes on the outer circle of the rotary ring, there is the multilayer magnetic medium which is made of magnetic material inside the separation box. When the rotary ring goes through the magnetic field, it would be magnetized and formed the high grade magnetic field. In the mineral processing, the mine slurry goes into rotary ring along with the gap of the magnetic pole and the magnetic particle would be attracted in the magnetic medium surface, revolving to the non-magnetic area. The magnetic particle would be put into the fine tank and the non-magnetic material goes into the tailing. Star Trace series vertical pulsation high gradient magnetic separator is installed with the stable pulsating device, which can make the mine slurry up-down moving repeatedly. The pulsating flow force makes the mine particle in the relaxed status that is effective to discharge the non-magnetic particle, improve the fine grade. Mean while, pulse pulp is conductive to the elimination of magnetic medium, increase the working efficiency.

Low Intensity Wet Drum Separator

STAR TRACE Wet Permanent Magnetic Separators are offered in sizes of Dia 1200mm and916mm in length of up to 3000mm. Three basic separator designs are available for cobbing, roughing and finishing /cleaning applications. Each type can be supplied in a single drum or multiple drum stages for taconite or magnetite and also for recovery for magnetic medium in dense media plants. The stationary magnet yoke is an assembly of strontium-ferrite permanent magnets. The rotating drum is available with optional rubber or stainless steel covers. The magnetic flux pattern will match the tank configuration for optimum performance. Star Trace magnetic wet separator dia 916 x 300mm is the smallest full scale separator in the 916 series and is primarily used for pilot plant tests. The separator can be delivered in concurrent, countercurrent and counter rotation versions.

Star Trace magnetic wet separator for laboratory use have drum dimensions dia. 600 x 285mm and dia. 200 x 100mm and dia are suitable for batch or continuous testing. The test results from the STAR TRACE laboratory separators correspond closely to those obtained in full scale operation.

Ball Mill

A Ball Mill a type of grinder is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints.

Ball Mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls. An internal cascading effect reduces the material to a fine powder.

Industrial ball mills can operate continuously fed at one end and discharged at the other end. Large to medium-sized ball mills are mechanically rotated on their axis but small ones normally consist of a cylindrical capped container that sits on two drive shafts (pulleys and belts are used to transmit rotary motion).

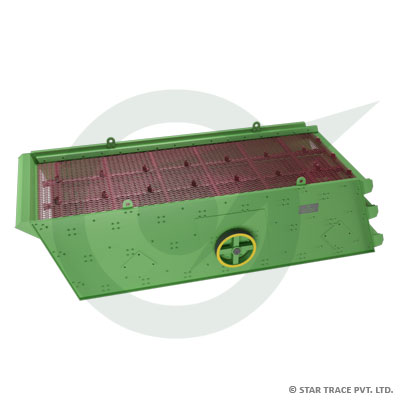

Dewatering Screen

Whilst enjoying immense popularity for many years on small horizontal and inclined screens, STAR TRACE is the first company in the India to perfect this simple drive arrangement on large horizontal and inclined screens.

This single development has resulted in tremendous advantages as far as reduced maintenance, compactness and simplicity are concerned.

Besides the simplicity of the drive, many other features have been incorporated to provide a machine which is specifically designed for heavy duty applications, long life and low operating and maintenance costs at a competitive price. The standard range of screens from 300x900mm to 3000x9000mm in single and multi-deck configuration.

Jaw Crusher

The crushing chamber of Jaw Crusher is composited by stationary jaw and movable jaw.The crushing work simulates the movement of animals which use two jaw crushers to crush materials.

Jaw Crusher is widely used in quarry, mining, metallurgy industry, building material, highway, railway and chemical industry etc.

The largest compression resistance of the material to be crushed is 320m pa. It is ideal for the primary crushing. It features high reduction ratio, easy operation, simple construction, repeatable performance, easy maintenance and low consumption.

Cone Crusher

STAR TRACE Cone Crusher adopts the international advanced techniques to develop this equipment.

The design of spring cone crushers structure is distinguish from traditional design and it compiles other advantage of various type of cone crusher.

So it is applicable to fine crush of superfine crush various ores, rocks, slag and refractories.

To adopt the techniques of concave and mantle after machining process to connecter with cone surface to instead the anciently complicate techniques, Star Trace cone crusher raise efficiency in rock crushing.

It has overload hydraulic cavity and refrigeration lubricating system, which fully ensure the safety and stability of operation. It is widely used in metallurgical mining, architectural, rock & railway etc.

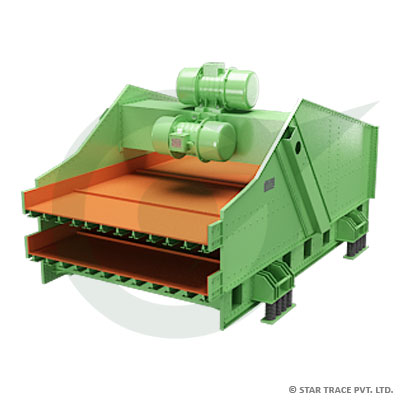

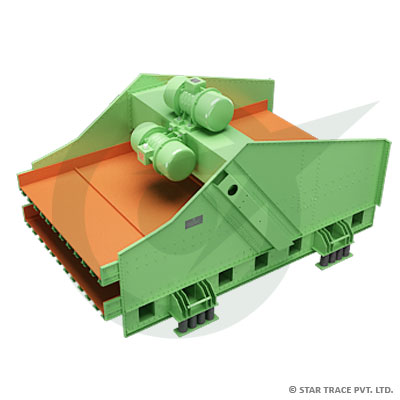

Inclined Vibrating Screen

The type universal Vibro Screen is a new generation vibratory screening machine characterized by low profile, efficient protection of support structure from vibrating masses and virtually noiseless operation.

The various versions of these Vibro Screens permit its use for wet and dry screening, coarse and fine separations and are widely used in steel mills, mineral beneficiation plants, chemical, mining, food and fertilizer industries, coal preparation plants and many others.

The standard range of screens from 300x900mm to 3000x9000mm in single and multi deck configuration.

Belt Conveyors

STAR TRACE takes the pleasure to introduce itself as one of the top most manufacturing, exporting and supplying units of Belt Conveyors based in India.

Designed to perfection, these belt conveyors are widely used in diverse industrial applications. We make use of good quality raw materials for manufacturing of these belt conveyors.

Thus our Belt Conveyors provide reliable performance and are very durable too. Made available in varied specifications, these belt conveyors are very affordable.

Applications- E-waste recycling plant

- Mining

- Metallurgy

- Coal industries

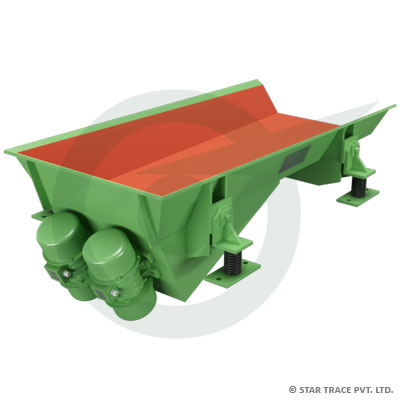

Vibrating feeder

STAR TRACE Heavy Duty Vibro Motor Powered Vibratory Feeder is a high frequency reciprocating machine of heavy duty capable on conveying bulk material from storage to processing or between processes at a continuous controlled rate of flow.

Thus Vibrating feeders are used in processing industries for handling all types of materials such as hot, damp, lumps, dusty or abrasive for various functions like flow of material from storage, proportioning blending, packaging, mixing, weighing, sprinkling, screening, scalping, crushing, washing, drying, heating, cooling, dusting, spreading, batching and etc.

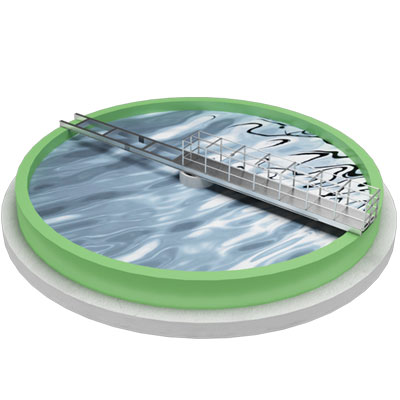

Hydroclones

Hydrocyclone widely applied in mine-chosen technique in various metal mines. It mainly shows in the following works:

- Classification for closed circuit grinding.

- Regrinding for fine mine classification.

- Mud-removing before selection and after selection.

- Dam and backfill for gangue.

In closed circuit grinding system, it features high classification efficiency and fine overfall fineness under high mine concentration. Classification efficiency is higher for 5-10% than common screw grader. It benefits for enhancing grader utilizing choose proper specification and mode of cyclone according to grinding processing capacity, overfall fineness and sedimentation concentration. This is precondition of getting the most optimized work condition.

Star Trace is able to offer standalone, parallel connection machine or machine series in such specification as Ø50, Ø75, Ø100, Ø125, Ø150, Ø200, Ø300, Ø350, Ø500, Ø660.

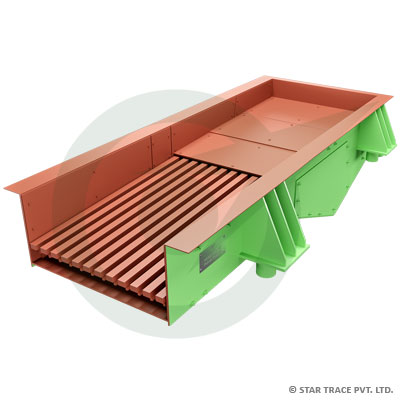

Grizlly Feeders

The Grizzly Feeder is suitable to feed primary jaw crushers, selecting the large sizes which require primary crushing, the smaller sizes, and any fines which must be eventually rejected. The Grizzly vibro feeder consists of a very large vibrating body made of thick plate, with inside lining of anti-abrasive plate. The Grizzly vibro feeder is driven by two or four vibrating motors. The vibro feeder which may either be placed on a steel or concrete base rest on springs.

Boosting throughout of primary crushers:

- A robustly constructed range of vibratory machines extending from units 0.5m wide x 2m long up to units 1.5m x 4.5m.

- The grizzly feeders are intended primarily for use ahead of primary crushers and are designed to handle large run-of-quarry stone, take the impact of dumped loads and smooth out the flow of material to the crusher.

- All models of grizzly vibro feeders have a flat reinforced impact area followed by a sloping grizzly bar section.

- The longer grizzly feeders are fitted with two stepped, grizzly bar sets. Replaceable wear sections of mild steel, manganese steel or rubber are fitted depending on the duty specified.

Floatation Machines

STAR TRACE designs and manufactures all sizes of flotation cells. Multiple impeller/diffuser configuration can be used to either enhance or restrain mixing depending upon the nature of the ore being treated.

The robust design allows the structure to be self-supporting and thus fewer supporting beams are requires for installation. Metallurgically the hydrodynamic shape eliminates short-circuiting and prevents sanding.

Specially profiled impellers and diffusers enhance efficient pumping of the slurry. Excellent dispersion of the external air feed and homogeneous mixing of the air and slurry all contribute to superior recoveries and grades being obtained. The impellers and diffusers are moulded rubber or polyurethane coated for abrasion resistance.

Leaching Process

Scrap printed circuit boards were selectively smelted at 200°C to produce a metallic alloy having three phases. These phases were identified as a lead-rich phase, a low tin content alpha bronze phase, and a high tin delta phase.

Electrochemical leaching method on this alloy were done in 1 mol/dm3 sulfuric acid or in 2 mol/dm3 hydrochloric acid (adjusted to an ionic strength of 3 mol/dm3). The lead rich phase was more strongly passivated in sulfate media, and in this medium the high tin content delta bronze was more resistant to corrosion than the lower tin alpha bronze phase.

In chloride medium the lead phase and both bronze phases corroded readily, but with current densities about an order of magnitude lower than in sulfate medium (static conditions) for the bronze phases. The high tin delta bronze phase was found to form a passivating layer in sulfate media. A similar layer was not seen in chloride medium.

The leaching method in sulfate medium also showed the existence of an alpha bronze phase of lower tin content in the centres of the alpha phase grains. This phase was quite resistant to leaching in sulfate medium.

STAR TRACE offer complete leaching process with highly cost-effective and environmental friendly process.

Screw Washers

Screw sand washing machine is mainly used for sand processing, electric pole factory, building work site and concrete dam, various sands classifying and dewatering.

The Screw Washer adopts inclination 15°, under the water tub, three weir plates form the sediment pool, the screw head is immersed in this pool, the screw is driven by electric motor through reducer rotating continuously, the fresh water is feeding from porous plate at bottom of sediment pool, this machine have three functions of washing, dewatering, classifying.